- Welcome to Next Degree

PRODUCTS Heat Sealers

-

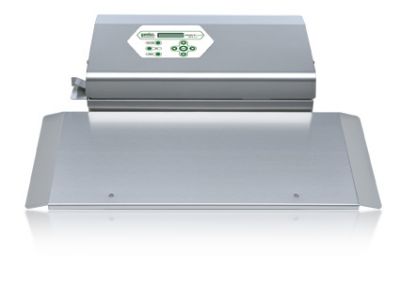

Gandus Vseal it

The only fully validatable medical pouch maker with CHEVRON SEAL for automatic production of sterilisable medical pouches starting from standard reels. Highly flexible and cost-effectiveness thanks to the possibility of fully customizing the production of every single pouch, by determining width, length and number of pouches to be manufactured using standard medical reels.

-

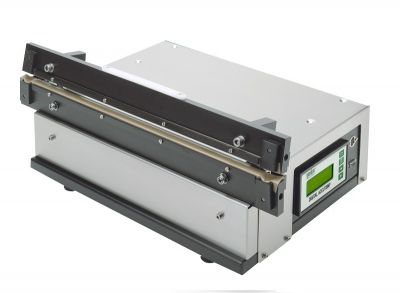

Gandus minirò H-lan touch

Fully validatable rotary medical sealer with sealing parameters control, setting touch screen and communication ports. It represents the ultimate evolution of Gandus Saldatrici production in medical field. A highly advanced software, developed on Windows® platform, allows communication with both CSSD and industrial applications. Data from the whole sealing process can be shared ensuring full validation to the ISO 11607 standard.

-

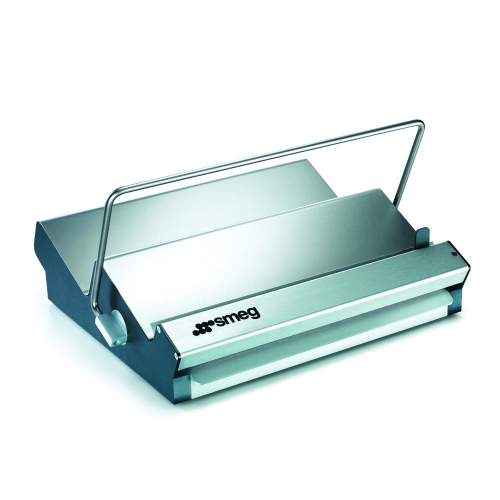

Melag MELAseal Pro

Sealing of sterilized packages is more reliable because the MELAseal Pro is validated without restriction by EN 11607. With each sealing procedure, the sealing temperature, the contact pressure and the throughput speed are monitored. The data acquired can be printed or archived electronically.

-

Melag MELAseal 200

The new validatable bar sealing device MELAseal 200 combines the proven merits of the successful MELAseal 100+ series with the advantages of larger rotary sealers. The MELAseal 200 complies with all the specifications of EN ISO 11607-2 as a matter of course. The MELAseal 200 sets new standards in terms of operation and documentation and is ready to operate after a short pre-heating time of app. 90 seconds. The sealing time amounts to three seconds. Packaging can be sealed successively without interruption. The large display and two integrated USB interfaces make the device extremely user-friendly. With 4 softkeys, an integrated user administration, a maintenance counter and a direct PC connection to the logging and sealing process, the MELAseal 200 is the benchmark for sealing devices of this class.

-

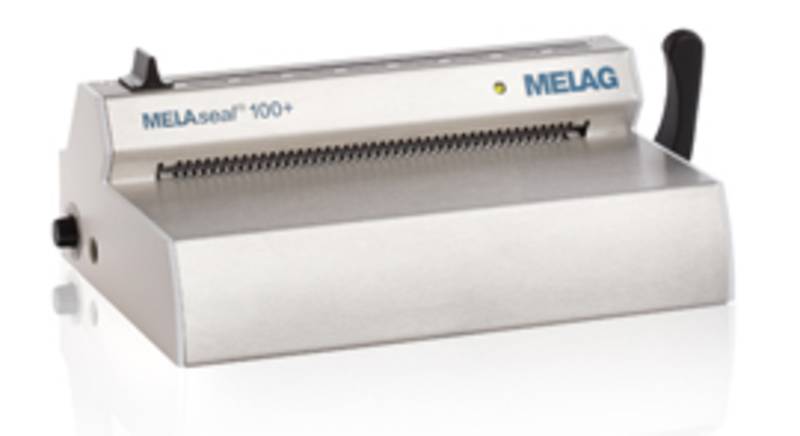

Melag MELAseal 100+

The new MELAseal 100+ combines the advantages of its predecessors, the MELAseal 100 and the MELAseal 101 in a single device. Efficiency, reliability and ease of use. After a brief preheating time of about 2 minutes, the foils can be sealed without a pause and with a width of sealing seam of 10 mm (EN 868-5 requires a minimum width of only 6 mm).